OPTIMIZING REPACKS

Overview:

Silo’s current repacking process to convert bulk produce was only supporting 1:1 conversions, so our users weren’t utilizing it. It was one of our top feature requests to optimize this experience so they could complete more complex repacks for customers and larger prospects.

About Silo:

Silo is modernizing challenges through cloud software in the produce industry. Industry users are produce distributors that come from decades old software or even pen and paper operations.

My role:

I was the lead designer for this work. I collaborated with product, engineering, and sales.

Duration:

Led design and research the first 6 months for initial release. Supported an additional 6 - 9 months to design and build additional capabilities.

$4.1B opportunity

Shippers are a huge opportunity for Silo, but sales had challenges tapping into this segment.

Our current functionality lacks the complexity needed to support their operations.

So we met with them to learn more.

Who are shippers?

They are large distributors that are closer to the growers, so they receive a massive supply of produce from across the border.

Let’s understand shippers.

We went to visit prospects in Arizona and Texas. Some had operations at a larger scale and were open to giving warehouse tours and providing insight on their current software experience.

Visiting team: Myself (design), product owner, engineers, & sales

What did we learn?

Pallet identifiers, advanced repacks, and PTI labels are a must have for us to unlock this segment in McAllen, TX and Nogales, AZ.

Repacks was a top request from our sales team’s prospects, so this work was a focus for the team to understand.

More on-site visits were done in McAllen, TX and Miami, FL for us to narrow in and do deep dives on the underlying complexity of repacks.

Why visit these locations?

TX, AZ, and FL are locations where produce is moved at a large scale from growers typically across borders.

What are repacks?

In the produce supply chain world, it’s when bulk produce is converted into retail friendly packaging.

For example: When leaf vegetables come from the farm in boxes and need to be repackaged into the plastic containers you buy in the grocery store today.

Repacking can be done either at facilities with growers, but a lot can also be done by larger businesses.

So what is Silo’s limitation today?

MINIMAL USE TODAY

Today it’s a bare-boned workflow, and users need more advanced functionality (ie. packing both kale and spinach into a mixed salad greens container).

Traceability is important from leaving the grower facility to landing in stores to sell, so users need to be able to add more details about the repack (ie. output lot numbers, weight, pack dates, and use-by dates).

At this time there was very low usage (21%) of this feature.

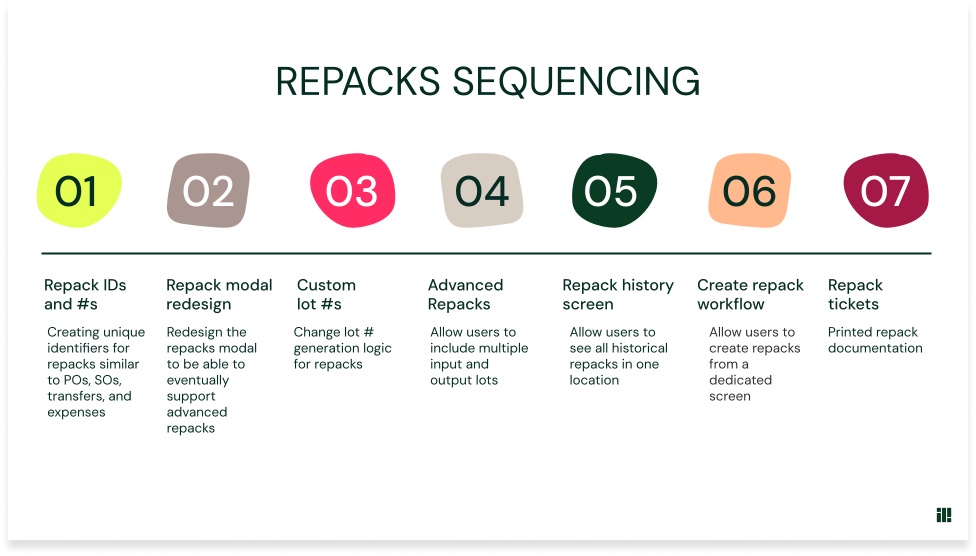

Our strategy to get the work done.

We worked towards sequencing work that included pallets and PTI labels because these would eventually affect the repacks improvements. Then we focused on how to tackle the repacks work so it became impactful early on.

Design Explorations

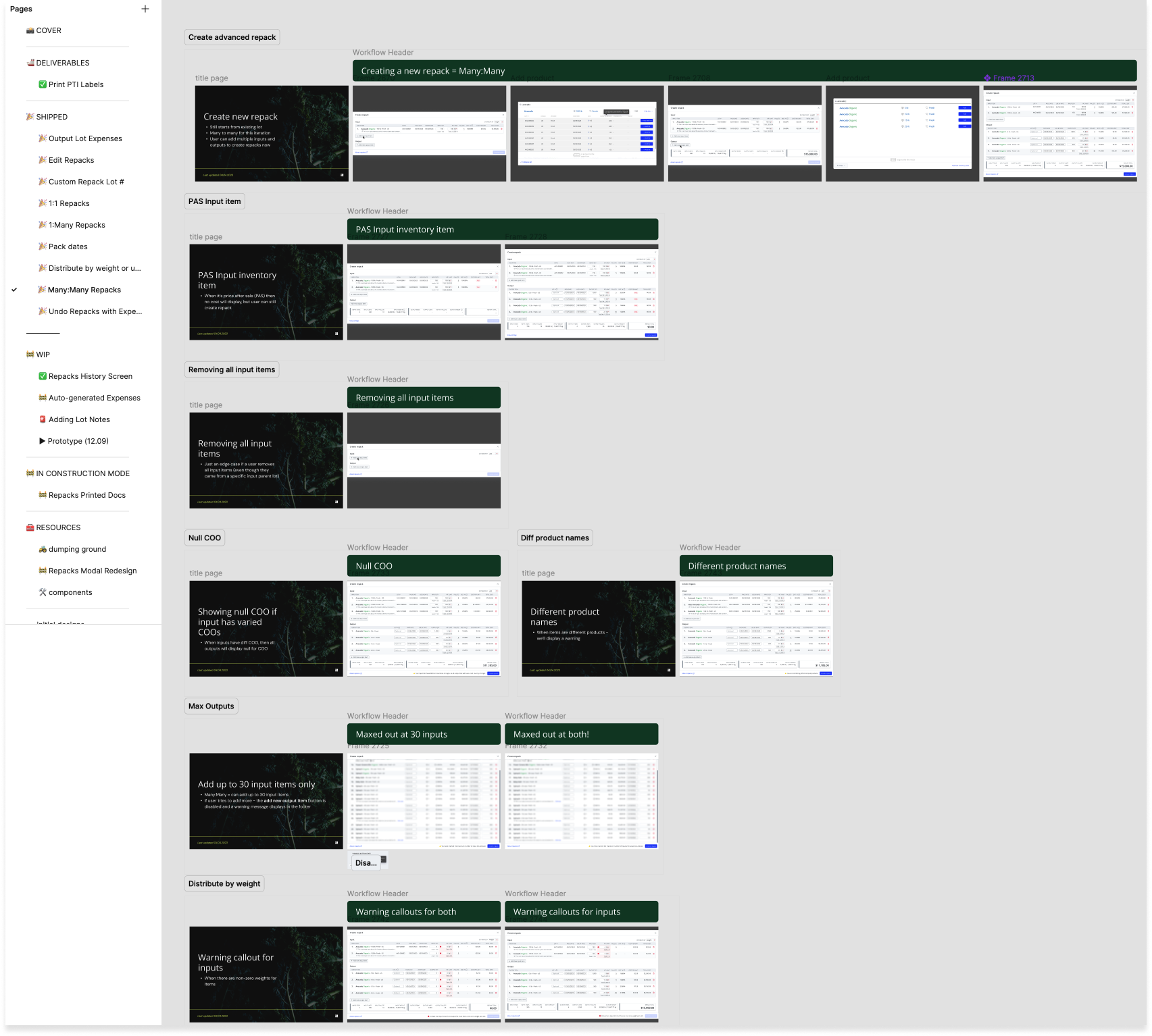

This was the opportunity to reimagine the repacks experience, scaling it to more complex scenarios. Even though we were starting with a 1:1 repack experience, I needed to explore more complex scenarios to see how it could scale and get vital user feedback.

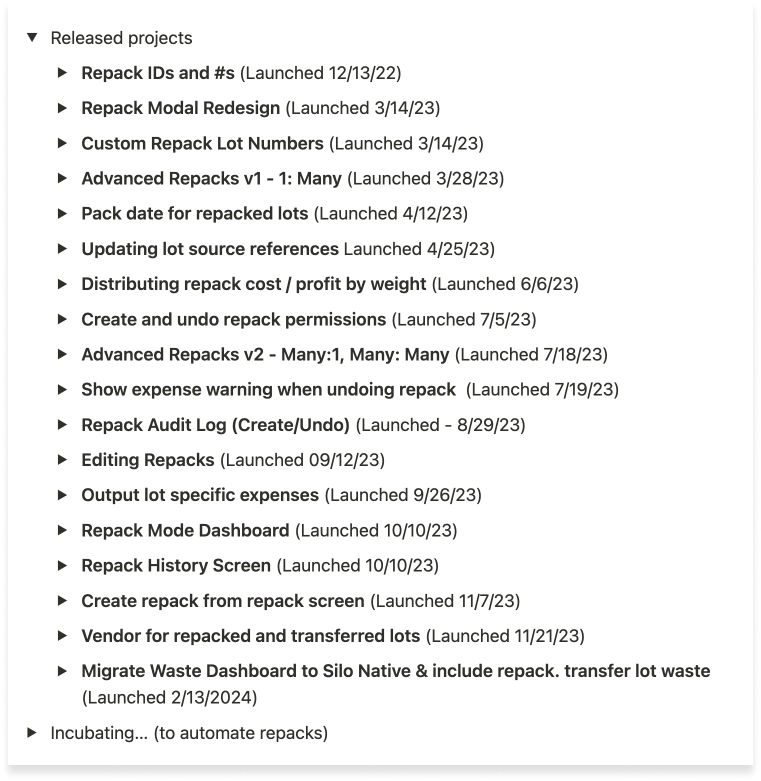

Getting the work done

There was an array of small to large projects to deliver a comprehensive repacks experience. We needed to sequence the work in a way where our current users would be excited to start using it and look forward to the updates.

Why do all this work? Getting any shippers to switch to Silo would require most of this work for them to be comfortable.

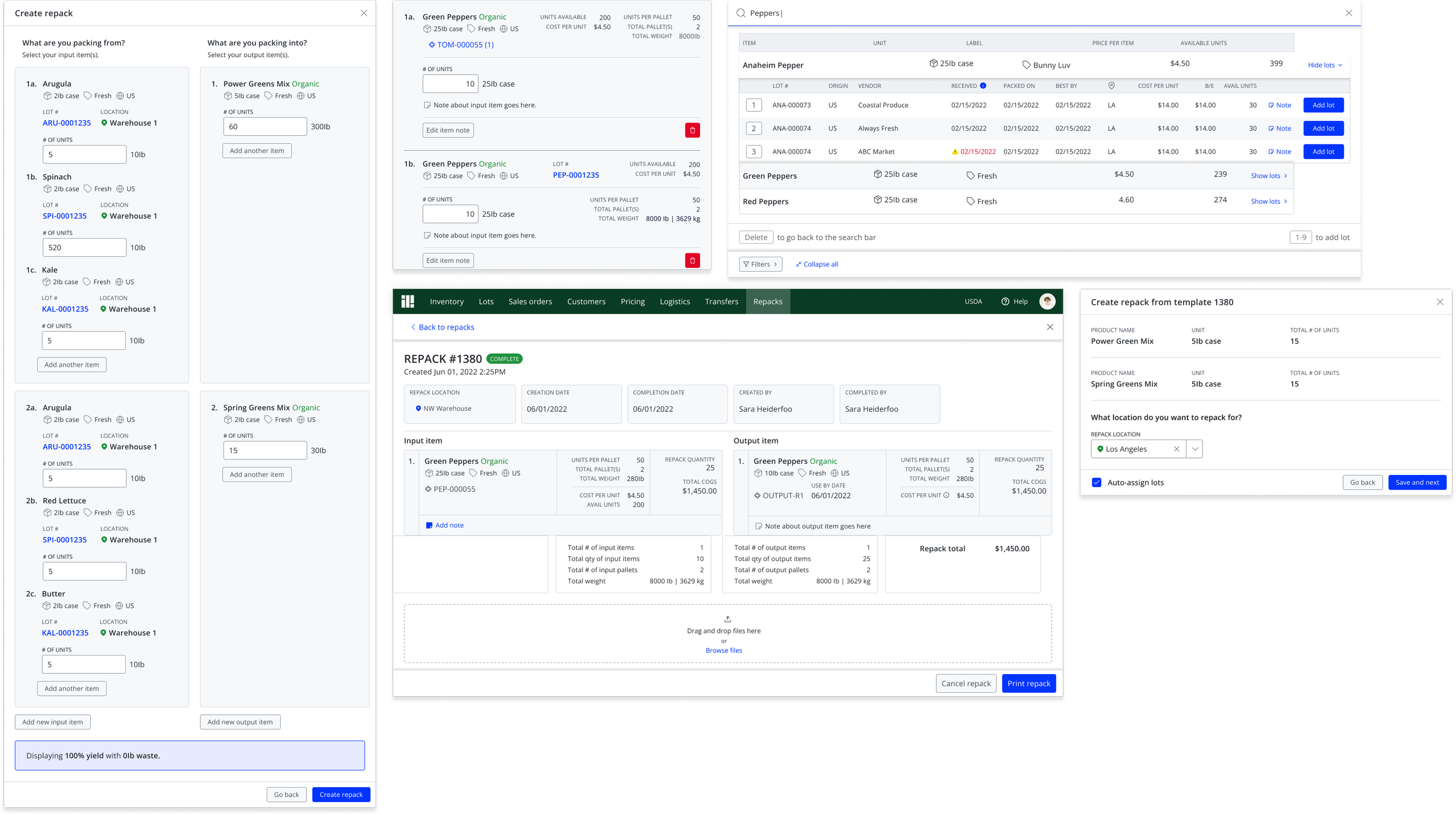

Final Designs | Advanced Repacks

Key Improvements:

Ability to create a many:many repack

Including pallet and weight data

Be able to add input and output notes

Allow users to add a custom lot # for output items

Include default packing dates and custom use-by dates

The Metrics

250%

Increase in

repacks creation

This also includes new core accounts who have switched over to Silo because of this work.

65%

Increase in task completion

This captures page impressions

to creating repacks.

*These metrics are based on data pulled from Feb - May 2024

$91M

Total GMV from newly added accounts

*Gross merchandise value annually

Outcome & Learnings

Doing this work debunked a lot of assumptions about lots.

This led our engineering team to improve how we calculate profits as it relates to output lots and figure out how to handle partially priced outputs.

*Lots: a group of product units that are assigned an ID to track performance and traceability.

Our users were starting to use the feature and wanted more.

Our current users were excited to start using advanced repacks, but now want us to include automating expenses as it relates to the repack items. We worked with a few that needed some workarounds.

It was important to break it into bite-sized chunks.

There was so much work to do which was overwhelming. Working together as a team, we kept each other honest on what was important and what needed to get cut.

The final strategy was tackling work iteratively, but in milestones in case the team needed to pivot.